SHIN KWANG HIGH-DENSITY CELLULOSE FIBER CEMENT (CRC) BOARDS General Description CRC boards are 100% asbestos free in composition.

These autoclaved composite materials are made from specially treated high grade cellulose fibre, Portland cement, refined sand & water. SHIN KWANG manufactures a wide range of CRC boards which are extensively used in residential, institutional, commercial and industrial buildings, as: Fascia / Siding, Internal Lining and Wall Partitioning Ceiling Soffit and Eave Lining Substrate for flooring Fire and insulation applications Decorative and innovative applications Roofing Exterior Wall Product Advantages Non Hazardous to Health 100% asbestos-free.

It is the leading manufacturer in Asia of asbestos-free, CRC boards. Since its inception in the 2,000's, the company has grown to become a major player in theCRC Boards industry.

CRC Boards, the flagship asbestos-free fiber cement board of Shin Kwang, made its debut in 2000, became an instant hit in the Korea market, and is now widely used in the region. Following the success of CRC boards has developed a products of other innovative calcium silicate boards and Magnesium boards. Today, its comprehensive range of fiber cement boards are widely used in applications such as roofing, cladding, partitioning, ceiling, external suffix, eave lining and substrate flooring, and in conjunction with other products in fire resistant and acoustic wall systems.

The fiber cement boards of Shin Kwang are now distributed in various countries in Asia, Europe, the USA and the Korea, Taiwan etc.

SHINKWANG believes in ensuring product quality and sustaining customer satisfaction. Since 2003, the company has been certified with MS ISO 9001,2000 for the "Manufacture of Fiber Cement Sheets (Smooth and Textured) and Fiber Cement Molded products".

The customers of Shin Kwang are assured of good quality products as well as caring after-sales service and continuous support from its experienced staff. Shin Kwang 's ultimate aim is the achievement of excellence in the products and services it offers. Shin Kwang welcomes and treasures feedback from its customers; such feedback forms the database for its continuous development programmed to create new, innovative and improved products and services that best serve its customers.

SHIN KWANG FACTORY Located in Zhe jiang Province of China . Spreads a total area of 38,000 square meters and 26000 square meters of floor area with a fixed asset of USD 616,000,000. SHIN KWANG, under technological cooperation with shanghai University, is committed to the development to the development of environment protective construction material. With 4 production lines respectively producing High Density Cellulose Fiber Reinforced Cement boards and High Density Cellulose Fiber reinforced calcium silicate boards as well as 7000,10,000-ton presser and high-pressure kettle, SHINKWANG reports an annual productivity of 15,000,000 square meters.

SHINKWANG boards have a high technological content and are recognized as the provincial scientific and technological Novelty. The products are tested by the National Cement and Concrete Products Inspection Center as well as the national supervising & Inspection Center for Permanent Extinguishing System and Quality of Fireproof Parts.

The enterprise, which has passed ISO9001:2000, is supplying markets in the US, Australia, Malaysia, South Africa, England, Singapore, Maldives, Middle East, Israel, South Korea, Hong kong , Taiwan and so on.

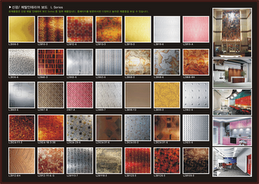

Brief Introduction of the Products

SHINKWANG CRC Boards take the major ingredient of high-grade fiber and mineral substance and are molded with the world's most advanced technology before specially treated under high-temperature and high-pressure.

Specifications

Size : 2440 * 1220 / 910*1820 / Optional surface sanding / Other optional Size available

Thickness (mm): 4T / 5T /6T / 8T /9T /10T / 12T/Other Thickness are Available

Main materials : Cellulose Fiber, Portland cement , Refined quartz sand & Water

Density (g/cm³) : 1.4 -1.8

Bending strength (M/mm²) : Above 11.8

Breaking load : Above 236

Adiabatic ability (w/m·k) : Below 0.188

Rate of length change (wetting %) : Below 0.16

Non flammability : Fire proof 1 st grade

Major Features

1、Good fireproof performance

2、Ideal anti-moisture performance

3、Long durability

4、High intensity

5、Permanent size

6、Heat insulation & sound insulation

Major Usage1、Inner & Outer Walling

2、Suspended Ceilings

3、Acoustic walling

4、Acoustic Ceilings

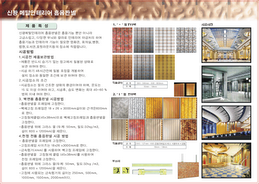

The Installation of Wall

1、Along top keel 2、Along floor keel 3、Horizontal keel 4、Vertical keel

5、Tapping screw 6、CRC boards

Installation Methods

1. Light steel keel frame

1)Draw the installation guideline.

2)Use the shooting nail or expansion bolt to fix the along top keel the along

floor keel on the ceiling and floor.

3) Arrange the vertical keel(usually 612mm) as per request and install

the horizontal keel.

2. Fixing method of the board

1) To cut the board as per the required size which is 10mm shorter than

the wall height.

2) The boards should be fixed on the keels with the tapping screws

leaving interlaced gaps, the distance between tapping screws is 200-250mm.

and each screw head should enter 0.5mm depth into the board.

3) Please leave a gap about 4mm in width between boards.

4) When fixing the board, it should be mounted from its center to the edges.

Don't fix it at different points at the same time.

Avoid the over bending of the board.

5) Before fixing we can place the mineral wool or glass fiber into

the empty space between the boards to get the better soundproofing and

fireproofing effects.

Small-sized CRC boards ceiling

1、T type key keel 2、T type sub keel 3、L type side keel 4、Boom 5、CRC boards

Installation Methods

1. Light steel keel frame

1) Draw installation guideline to determine the center distance of the boom,

usually 1200mm.

2) Use the tapping screw to fix the sub-keel on the walls around the ceiling.

3) Use mental boom to fix the T-keel into the T-type key keel, the distance

between them is 600mm or 610mm.

4) Insert the T type sub-keel into the T-type key keel, the distance between

them is 600mm or 610mm.

5) Then place the CRC board on the T-type keels.

2. Attention:As per the different projects (if it is very big ceiling decoration projects),

you should install the UC38 light steel keel on the T type key, use the hook fitting to link

the boom and UC38 light steel keel.

When the clients want to use our perforation board, we can put

a layer of sound absorption mineral wool on the UC38 light steel keel so

we will have better heat insulation and sound absorption effects.

Caution of Storage, Transportation and Other ItemsStorage

1.Our boards will be dehydrated before delivery, so we should place

it on the flat dry warehouse ground.

2. Each pallet of them should be covered with the tarpaulin or put into the nylon bag.

3. In the storage place of our products we should avoid the edges and angles being damaged

by the automatic and artificial operations.

4. Can not put the boards vertically.

5. The height for each pallet of products is 1.2m; If you want to pile up

the pallets then the total height of them should be less than 3.0m.

Transportation

When you load and unload it or install it you should carry and put is

carefully so as to avoid the edges, surfaces and angles being damaged

meanwhile we should not over bend it in order to protect it.

Cutting

Just like cut wood and the other building materials when you use

the electrical cutting tool cut our products it will cause the flying dust

and powder, so the worker must wear the gauze mask, the working site

should have ventilation and should clean up the dust after working.

Application

1 comment:

hello,im keen on knowing more about your fireproof produts.Is it is feasible to construct entirely fireproof and blast proof building?

waiting for your reply.thank you

Post a Comment